Transform your plant into a “Well Oiled Machine” for increased productivity and profits

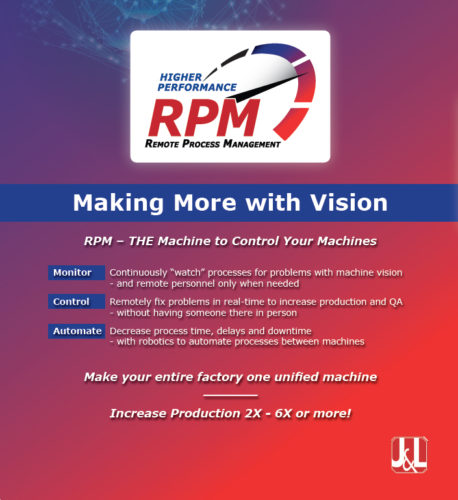

For the last 45 years, we have been an industry leader in providing machine tool, rebuild, repair, and maintenance solutions that help you bring sanity back to your shop floor. We have partnered with J&L to provide a Remote Process Management (RPM) system that will help you transform your plant into a “well oil machine” for increasing productivity and profits.

RPM dramatically increases productivity and profits, while reducing risks by integrating the following unique features:

- Visual cues from real-time and archival video and images help you identify the root cause of your machine failures

- Real-time alerts from visual cues or feedback from IoT sensors enable your team to react to problems that could jeopardize your production from anywhere in the world.

- Historical Data provides you with the information that allows you to understand what happened and troubleshoot new processes and programs faster.

- Integration of multiple technologies into a streamlined user interface. For example, side by side, optical and thermal imaging can be used to monitor machine temperature.

This functionality can help you improve machine productivity, by 2-6X in addition to protecting your Machines, Facility, and Team. We would love to have the opportunity to learn more about the unique challenges that are contributing to the chaos in your machining operations. Restore your sanity & contact us today!